We were lucky enough to be invited on a field trip to go and see the Burton showroom, leaving the groady pit of central London, and venturing through the countryside to an industrial estate on the outskirts of Bracknell.

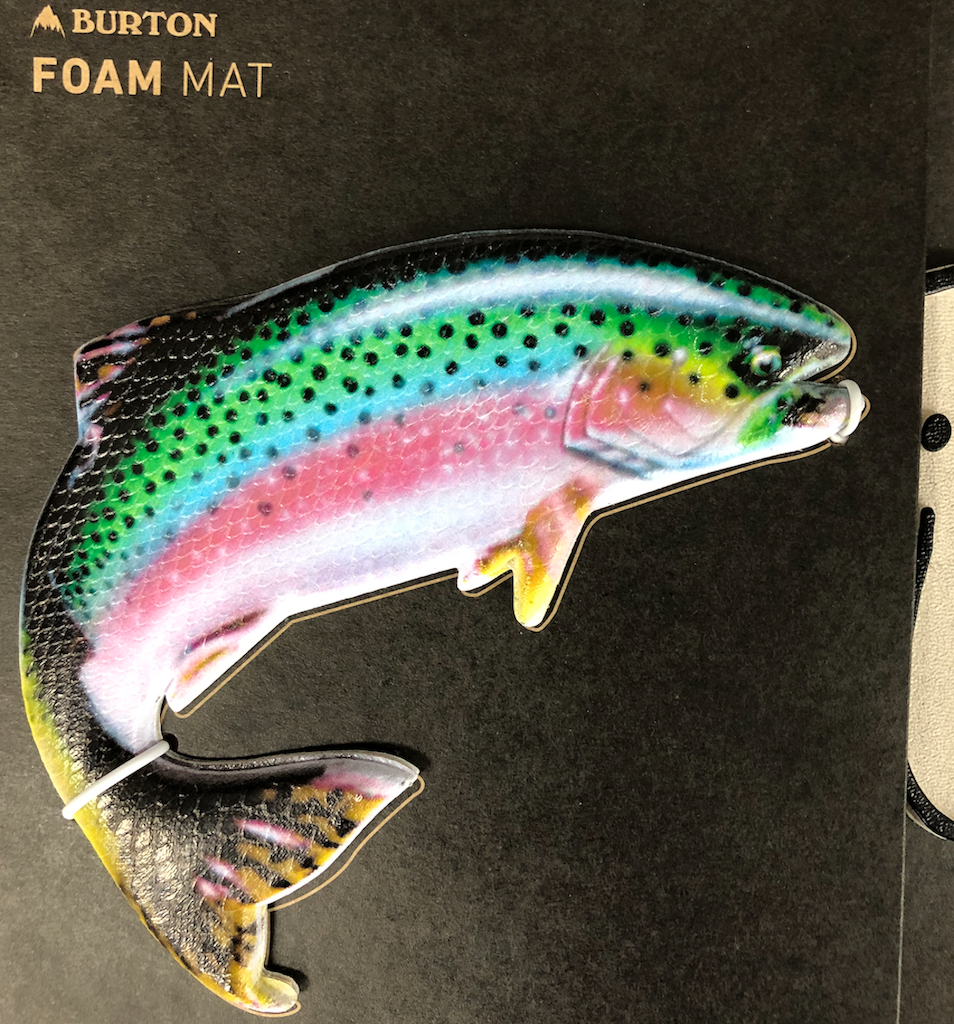

Burton have been quietly working behind the scenes to try and ensure that their company is one that is making more socially and environmentally conscious decisions. As such they’ve made the move to go completely lacquer-less with their topsheets for their snowboards, which is way better for the environment, and leaves the boards with a pretty cool matte finish. They’ve also continued to use their Super Sap resin which is formulated with bio based materials and reduces the carbon footprint by 50% compared to a traditional epoxy. Burton have also introduced a new range of Foam Mats into their line – made of algae… Yeah, that stuff you find swirling on top of a pond. We know it sounds weird, but it’s actually a pretty cool process, and generates a lot less waste than the traditional methods, plus the finished product feels just like normal foam.