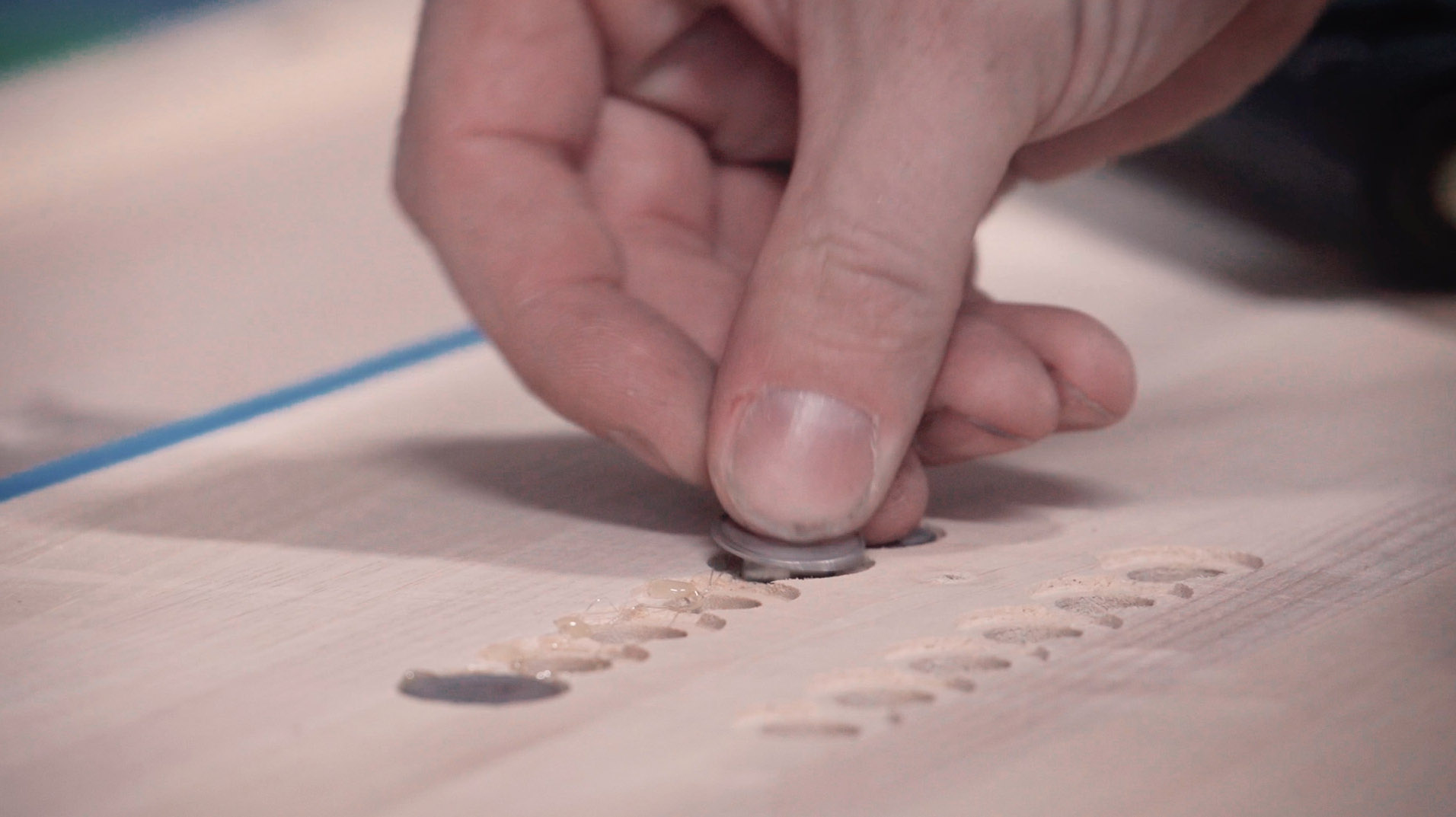

Whilst it’s unlikely that you’ll ever get the chance to make a snowboard yourself, it’s fun to find out exactly what’s inside a board and how they get put together. If nothing else, it helps to make sense of some of the jargon that snowboard companies like to wrap their products in!

After we finished shooting The Snowboard Workshop videos in the DOUK factory, they were kind enough to show us the build process from start to finish. They hand produce every single board they produce using the tools, presses and jigs in their factory, many of which they made themselves. Stay tuned for details on how to win the board you can watch being built above.