There are two universal truths in snowboarding. One: boots are the most important bit of kit you’ll ever own. And two: they’ll never get the credit they deserve.

At every turn, the humble boot faces an uphill battle for recognition; boards get all the attention, for obvious reasons, but even bindings and goggles are flashier – and neither of those start to smell after a bit. Then there’s the fact that boots often only get noticed when they perform badly, and mostly appear all in black – an unwelcome parallel if ever there were one.

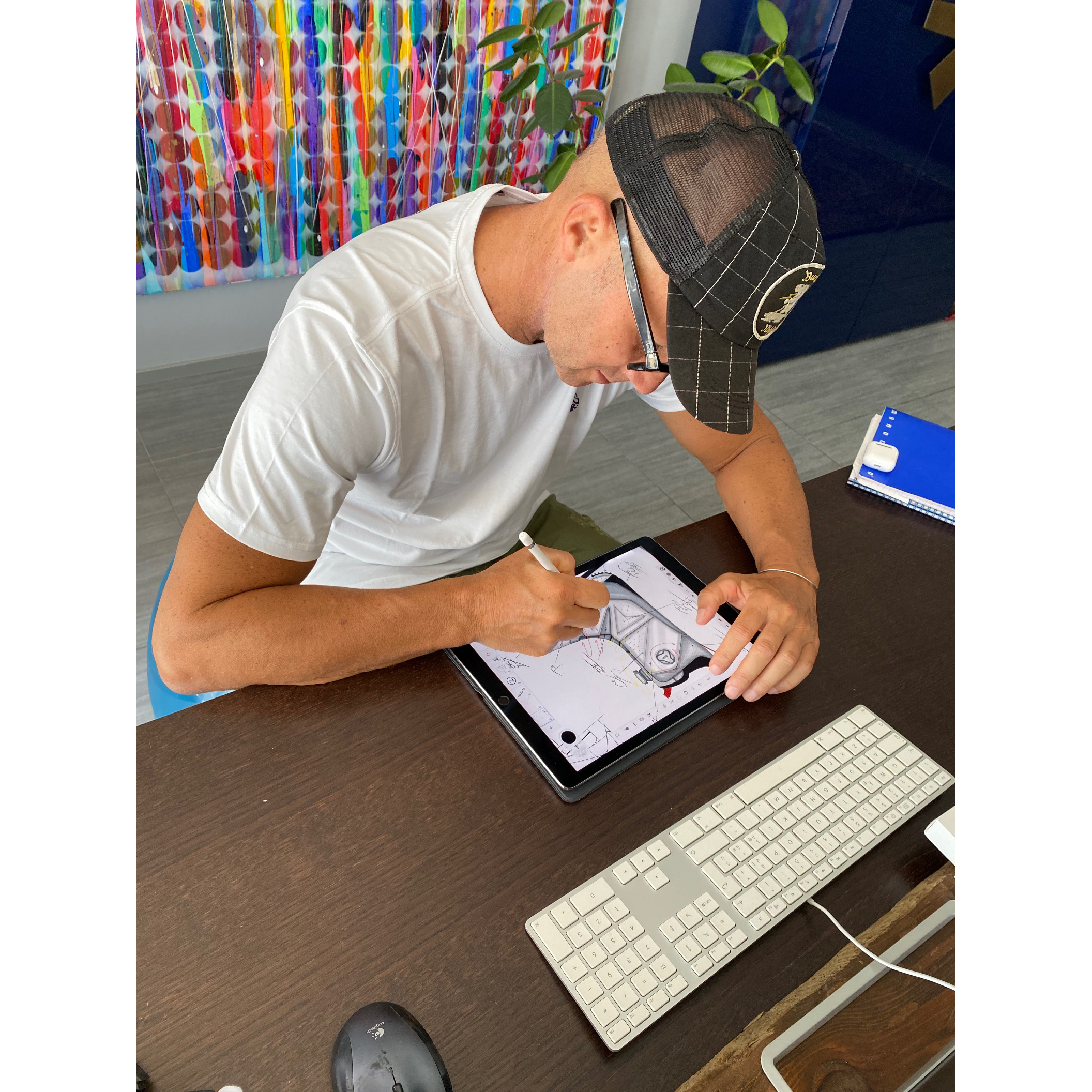

While they could do with better PR, boots are truly the unsung heroes of the snowboard world – and without wanting to get too Inception-y, that would make Maurizio Molin one of the unsung heroes behind the unsung heroes. As an artist and designer, he’s been involved in crafting snowboard goods for over 25 years. During that time he’s turned his hand to everything from boards and eyewear to early step-in systems, and at one point led a hand-picked team at one of the biggest names in the game. Away from snowboarding his fingerprints appear on sneakers, perfume bottles, ski boots and much more, and in warmer months he can be found cleaning up on the gondola-racing circuit in and around his native Venice.

“There are two universal truths in snowboarding. One: boots are the most important bit of kit you’ll ever own. And two: they’ll never get the credit they deserve”

Plenty to keep him in Cornettos, then – but despite all these strings to his bow, designing snowboard boots is something he keeps coming back to. Now working for Nidecker, he’s recently overseen a seismic shake-up of the Swiss brand’s range. It’s a huge achievement by anyone’s standards, but for a designer it must be odd knowing that the vast majority of his work is destined to be buried under pant cuffs and binding straps. We can’t help but wonder what the appeal is – and as it turns out, we’re not alone: “I’m asking that too sometimes!”

Perhaps it’s the fact that the world of laces and lasts was his entry point into the snowboard industry, back in 1995. Then, as now, one of the biggest brands in snowboarding was Italy-based Northwave. While working for a design firm (“I was on the fashion internship, it was a little bit boring…”), and as a recent ski-to-snowboard convert, he jumped ship to work on their boot line – and eventually, their iconic fat-soled shoes.