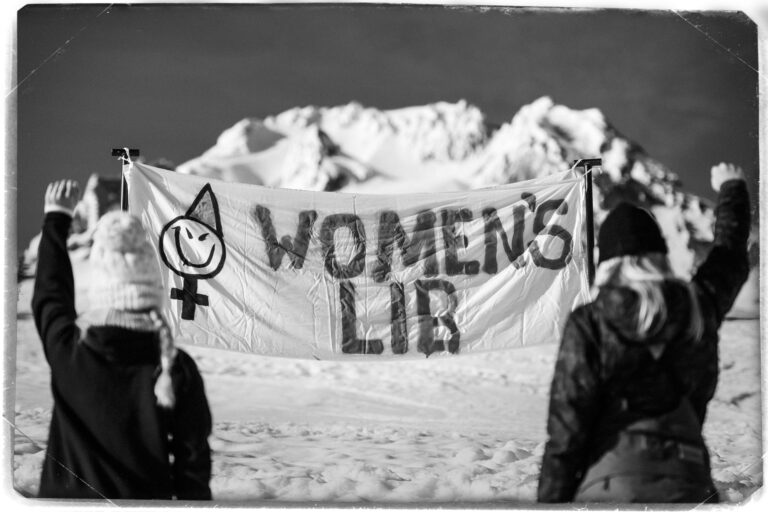

How often do you stop and think about who and how your snowboard apparel was made? Do you think about it when you buy it or when you wear it, or maybe only when you read an advert that gives a glimpse into the process. We are a subculture fuelled on gear chat, reviews and sneak peeks on what’s coming next season. As the world becomes more active in the conversation around climate and sustainability, so should we with our awareness around our products and how they are made. We have a lot of power as consumers and the more we ask for this information or demand how our products are made, the more brands will bow down.

This week, Patagonia launched their Shell, Yeah! campaign and in doing so they become the first in the industry to make all their shells with recycled materials and sew them all in a Fair Trade Certified factories. It’s not simply a one-off product for marketing, not only a set of two jackets, but the whole line across snow, alpine and hike, including the new SnowDrifter jacket. The focus for this collection is around causing less harm with their environmental footprint and supporting the people who build the product whilst the product remains fully technical for shredders to rely on. We find out about how they did it and how we can be consumer conscious as snowboarders…

How difficult was it to make a whole collection of 62 jackets fairtrade sewn whilst also being recycled and technical?

Wendy Savage – Director of Supply Chain Social Responsibility & Traceability: It is very difficult to make a whole collection recycled, fairtrade and technical – it was years in the making and took a lot of aligning internally. Our team in materials had to wait for materials to be available in a recycled quality and, not only available, but to have the exact same properties so we could make a product that is long lasting. On the recycled side alone it took a while and was very difficult. On the social responsibility side, this product line is made in 2 or 3 different factories so it took us a couple of years to work with them to get it right. They were already on the Fair Wear Foundation for years but they still had to pass the next level of requirements from Fairtrade. They collaborated with the thousands of workers at each of the factories to decide how they wanted to use the premium that they were going to make as part of the Fairtrade program. Organizing all of those things before we could come out and say, we did it, was a full company effort.

Why in particular do you think the core sports community should care about how their clothes are made and by who?

We wouldn’t have apparel or anything without workers behind it. There is an extreme level of poverty within the supply chain and this is important to address especially for consumers nowadays. They are looking for brands to take responsibility around this topic. But it is also the responsibility of the consumer to help push for change. This can be lacking in other brands who are not willing to engage in helping improve the lives of workers around the world. It is even a struggle for us at Patagonia when we go to partner with other brands to make this change for more workers. So, if a customer doesn’t ask the question, who makes my clothing, then brands and factories might not have a tangible need to work on this. Customers may be asking for quality or different colours, and the brands answer them, but we want more customers to ask who made my products and how are they made. I think in the outdoor sport community customers are much more in tune with, not only the environment, but also our human rights.

Consumers have rights. You are giving brands money for this product so you need to demand the information. I have been working in Social Responsibility for 17 years and when I started my career the consumer was not so open to asking questions of brands, it was coming from the NGO community. That has shifted completely! The brands that are not looking at this area in their supply chain now are going to be left behind – we are trying to get more brands to join the movement but we need more consumers to join and care about it too!